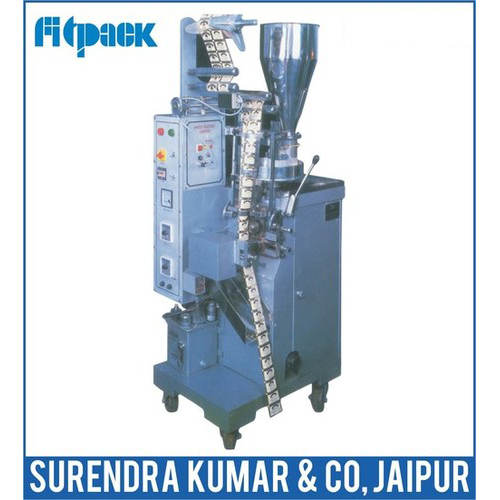

Weigh Filler Machine

300000 INR/Unit

Product Details:

- Features User Friendly Operation, High Accuracy, Fast Changeover

- Filling Range 10g - 2kg

- Application Granules, Seeds, Pulses, Spices, Dry Fruits, Snacks

- Power Supply Single Phase

- Noise Level <70 dB db

- Usage Industrial Packaging

- Type Weigh Filler Machine

- Click to View more

X

Weigh Filler Machine Price And Quantity

- 1 Unit

- 300000 INR/Unit

Weigh Filler Machine Product Specifications

- Approx. 900 x 800 x 1800 mm Millimeter (mm)

- Industrial Packaging

- <70 dB db

- Weigh Filler Machine

- 1.5 kW Watt (w)

- Silver

- Other

- Stainless Steel

- Single Phase

- Automatic

- Yes

- Electric

- Granules, Seeds, Pulses, Spices, Dry Fruits, Snacks

- 220V / 50Hz Volt (v)

- Approx. 250 kg Kilograms (kg)

- 10g - 2kg

- Other

- Other

- User Friendly Operation, High Accuracy, Fast Changeover

Product Description

High-technology Weigh Filler is available in sturdy and strong stainless steel body to resist corrosion and rusting. This is one of the most accurate weigh fillers provided with two or four filling valves for efficient filling of a range of materials from liquids to semi-liquids. It is designed to efficiently fill oils & fats, shampoo, cheese, sugar, syrup, mayonnaise etc. It comes with sturdy and hygienic body with swing doors to provide maximum safety to the packed products. This is the most compact and accurate Weigh Filler available with high packaging speed and productivity.

Advanced Weighing Technology

This weigh filler machine employs a digital LCD display and computerized PLC control for highly accurate product dispensing. Its single-head mechanism, paired with a vibratory hopper and pneumatic gate, ensures consistent weight measurement and fast changeover for different batch sizes, supporting a filling range from 10 grams to 2 kilograms.

Versatile Packaging Applications

Designed for industrial packaging requirements, the machine is compatible with a variety of product formats including pouches, jars, and containers. It supports sealing with most machines and is well-suited for packing products like granules, seeds, dry fruits, pulses, spices, and snacks, making it ideal for distributors, manufacturers, and exporters.

Durable and Hygienic Construction

Built with food-grade SS 304 stainless steel and available in both mirror and matte finishes, the machine meets stringent hygiene standards. The IP54 protection level makes it reliable in demanding environments, and the adjustable support stand ensures smooth operation for different bag sizes and types.

FAQs of Weigh Filler Machine:

Q: How does the weigh filler machine ensure precise filling for various products?

A: The machine uses a digital LCD display and a computerized PLC control panel to measure and dispense accurate quantities. Its vibratory hopper and pneumatic gate discharge method deliver controlled and consistent product flow, achieving high-precision weighing for granules, seeds, pulses, spices, and snacks.Q: What is the recommended process for operating this weigh filler machine?

A: To begin, load the product into the vibratory hopper, adjust the bag support stand as per the packaging format, set the desired filling parameters on the touch panel interface, and initiate automatic filling. The PLC system manages weighing and discharge, while filled packages are ready for sealing or further processing.Q: When should routine maintenance be performed on this machine?

A: Periodic lubrication of the moving parts is advised to ensure optimal operation and longevity. Routine inspections should be scheduled based on usage frequency, with attention to the pneumatic gate and vibratory hopper components as recommended by the manufacturer.Q: Where can this weigh filler machine be installed for best results?

A: This machine is designed for industrial packing lines and can be installed in manufacturing, distribution, export, or trading facilities. Its compact design (approx. 900 x 800 x 1800 mm) allows integration into existing production environments with single-phase power supply requirements.Q: What types of packaging is the machine compatible with?

A: It is compatible with pouch, jar, and container filling, suitable for a wide range of sealing machines. The adjustable bag support stand facilitates changeover, making it versatile for different product weights and packaging formats.Q: How does the user-friendly operation benefit production efficiency?

A: The touch panel interface, single head operation, and fast changeover features streamline the filling process, minimize operator training time, and reduce downtime for batch changes. This enhances productivity and ensures high accuracy across varying product types.Q: What are the key benefits of using this weigh filler machine in industrial packaging?

A: Users benefit from high-precision weighing, automatic operation, low maintenance requirements, hygienic construction, and compatibility with diverse products and packaging formats. Its robust performance and PLC-controlled accuracy support reliable, efficient packaging for various industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |