Mon to Sat: 9:00am to 6:00pm

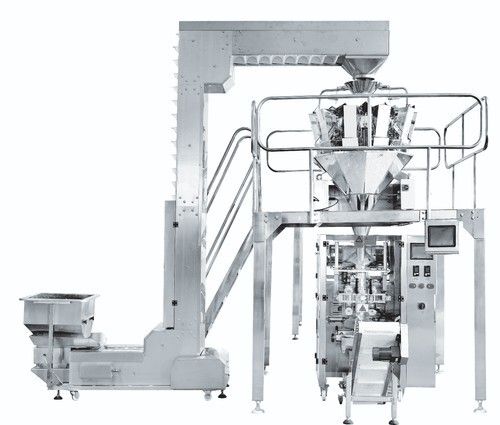

Vffs Packaging Machine

1500000 INR/Piece

Product Details:

- Noise Level 75 dB

- Filling Range 10-1000 g

- Power Supply Single Phase

- Features Touch Screen Interface, Easy to Operate, Servo Motor Controlled

- Usage Industrial Packaging

- Application Food, Pharmaceutical, Chemicals, Granules, Powder Packaging

- Type VFFS Packaging Machine

- Click to View more

X

Vffs Packaging Machine Price And Quantity

- 1500000 INR/Piece

- 1 Piece

Vffs Packaging Machine Product Specifications

- 2 kW

- 220 V

- Multi-Function Packaging Machine

- 75 dB

- Center Seal / Three Side Seal

- Automatic

- 450 kg

- Electric

- 35-65 Bags/min

- VFFS Packaging Machine

- Touch Screen Interface, Easy to Operate, Servo Motor Controlled

- Industrial Packaging

- Yes

- PLC

- Single Phase

- Low Noise Operation, High Performance, Corrosion Resistant

- 1200*850*1900 mm

- Stainless Steel

- Silver

- Food, Pharmaceutical, Chemicals, Granules, Powder Packaging

- 10-1000 g

Vffs Packaging Machine Trade Information

- 50 Piece Per Month

- 2-3 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

VFFS Packaging machine we deal in is highly suitable for the applications, wherein there is a need to wrap a particular amount of product in the bag. Offered is an important equipment suited for product packaging. The automatic packaging machine we deal in is efficient as well as accurate. It has several functional benefits as well as superb characteristics. The said machine is accessible with automated features. VFFS Packaging machine is an advanced packaging machine, suited for easy and efficient operation.

Advanced Packaging Efficiency

This VFFS Packaging Machine integrates automatic controls and a servo motor-driven system to deliver consistently high-speed output and packing accuracy. Its adaptable bag and filling range, robust stainless steel construction, and touch screen interface reduce operator effort and maximize production efficiency even in demanding industrial settings.

Versatile Material Compatibility

Engineered to handle a variety of flexible packaging films, the machine easily processes Laminated Film, PET/PE, Paper/PE, and BOPP/CPP. This versatility helps ensure reliable and high-quality seal integrity, meeting the unique requirements of food, pharmaceutical, and chemical packaging operations.

FAQ's of Vffs Packaging Machine:

Q: How does the VFFS Packaging Machine ensure high packing accuracy for different products?

A: The machine uses a servo motor and PLC control system to accurately measure and dispense product quantities, achieving packing precision of 1%. Optional hoppers-volumetric, auger, or weighing-allow tailored handling for granules, powders, or liquids, maintaining consistent bag weights throughout production.Q: What types of film materials can be used with this packaging machine?

A: The VFFS Packaging Machine is compatible with laminated film, PET/PE, Paper/PE, and BOPP/CPP materials, up to a maximum film roll width of 420 mm. This feature enables packaging across varied applications, including food, pharmaceutical, and chemical industries.Q: When is center or three-side seal preferred for packaging?

A: Center seal is typically chosen for bulkier or longer items, offering strong vertical sealing for high-speed continuous packaging. Three-side seal is suited for smaller portions or when enhanced protection against external factors is needed, providing reliable sealing and package integrity.Q: Where can this packaging machine be installed for optimal performance?

A: Due to its compact dimensions (1200*850*1900 mm) and low noise operation, the machine can be installed in industrial production facilities, packaging rooms, or processing plants. Its corrosion-resistant stainless steel body ensures compatibility with humid or food-safe environments.Q: What is the typical process flow when using this packaging machine?

A: The process starts with loading film rolls and filling material into the selected hopper. The PLC-controlled system sets bag length and width parameters via touch screen. Film is automatically formed, filled, and sealed-either center or three-side-while finished bags are conveyed out for collection.Q: How does the LCD touch screen interface benefit machine operators?

A: The LCD touch screen simplifies machine setup and operation with multi-language support, intuitive controls, and real-time monitoring. Operators can easily adjust parameters for bag size, filling range, and sealing type, reducing setup time and minimizing operational errors.Q: What are the main advantages of using this VFFS Packaging Machine?

A: Key benefits include high packaging speed (35-65 bags per minute), low noise, adjustable bag sizes, flexible filling options, and compatibility with multiple film materials. The automated, computerized system ensures efficient operation and reduces manual intervention, boosting productivity and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

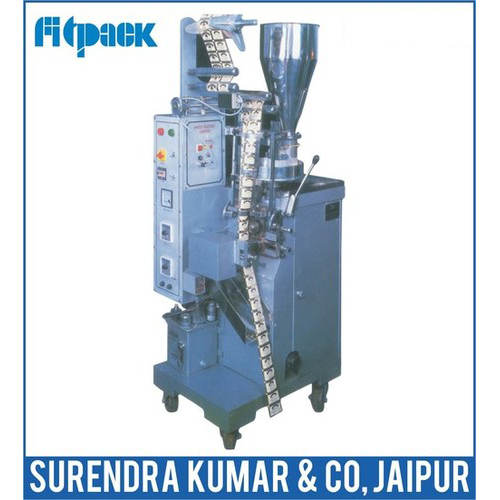

Other Products in 'Packaging Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |