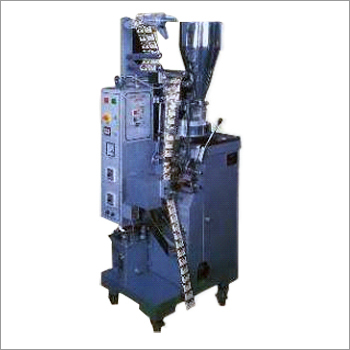

Mechnical Cup Filling Machine

60000 INR/Unit

Product Details:

- Product Type Mechanical Cup Filling Machine

- Material Stainless Steel

- Application Other

- Packaging Material Other

- Computerized No

- Automatic Grade Semi-Automatic

- Drive Type Gear & Motor Driven

- Click to View more

X

Mechnical Cup Filling Machine Price And Quantity

- 1 Unit

- 60000 INR/Unit

Mechnical Cup Filling Machine Product Specifications

- 220V AC, 50Hz Volt (v)

- Mechanical Cup Filling Machine

- Approx. 200 kg Kilograms (kg)

- Semi-Automatic

- Other

- No

- Gear & Motor Driven

- 1100 mm x 700 mm x 1700 mm Millimeter (mm)

- Silver

- Other

- Stainless Steel

Product Description

Acknowledged in the business enterprise as a manufacturer, Exporter, Service Provider and Supplier, we are engaged in offering a wide range of Mechanical With Cup Filling System that is used crosswise various industries to perform industrial usages. Our occupational are aided by sophisticated technology in manufacturing these precisely technologist machinery. These products are in widely demanded in the market for their unmatched properties. To ensure the procurement of the Mechanical With Cup Filling System, our team of qualified professional test all the product for flawless delivery at our customers' end.

Features:

- Robust construction

- Corrosion resistance

- Easy to handle

- Superior performance

Efficient and Accurate Cup Filling

Achieving a filling accuracy of 1%, this Mechanical Cup Filling Machine streamlines the packaging process for dairy, water, or juice. Precise gear and motor-driven operation ensures consistent results across cup sizes ranging from 50 to 500 ml. The device suits businesses seeking high throughput and reliable quality.

Robust Design for Diverse Environments

Built from corrosion-resistant stainless steel, the machine withstands demanding conditions and supports a wide operating temperature range (5C40C). The IP54 protection class and emergency stop switch enhance operational safety, and easy-to-clean components reduce maintenance needs over time.

FAQs of Mechnical Cup Filling Machine:

Q: How does the Mechanical Cup Filling Machine ensure accurate filling volumes?

A: The machine utilizes a gear and motor-driven mechanical system to dispense precise volumes, maintaining a filling accuracy of 1%. This mechanism allows for consistent and repeatable results, whether filling 50 ml or 500 ml cups within the specified diameter and height range.Q: What is the process for changing cup sizes on this machine?

A: Changing to a new cup size is straightforward and takes approximately 10 minutes. Operators adjust guide settings to accommodate containers with diameters between 50 and 95 mm and heights from 40 to 120 mm. Installation support is available to assist with initial setup and changeovers.Q: Where can the machine be installed and what support is provided?

A: This machine is suitable for facilities engaged in dairy, water, and juice packaging within India. As a distributor, exporter, manufacturer, supplier, and trader, installation support is available to guide users through setup and commissioning, ensuring seamless integration into existing packaging lines.Q: What benefits does the machine offer to small and medium-sized businesses?

A: The Mechanical Cup Filling Machine provides reliable, high-speed cup filling with minimal maintenance demands. Its semi-automatic operation and simple controls make it accessible for staff, while its compact design and corrosion-resistant frame maximize efficiency and longevityeven in challenging production environments.Q: Can this machine fill both plastic and paper cups for different applications?

A: Yes, the machine is compatible with both plastic and paper cups, supporting versatile filling needs across dairy, water, and juice production. Cup feeding can be set up for either manual or automatic operation, depending on workflow requirements.Q: How is operator safety maintained during machine operation?

A: Operator safety is prioritized with the inclusion of an emergency stop switch and an IP54 protection rating. These features help prevent accidents and equipment damage in case of unexpected events, aligning with modern workplace safety standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Filling Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |