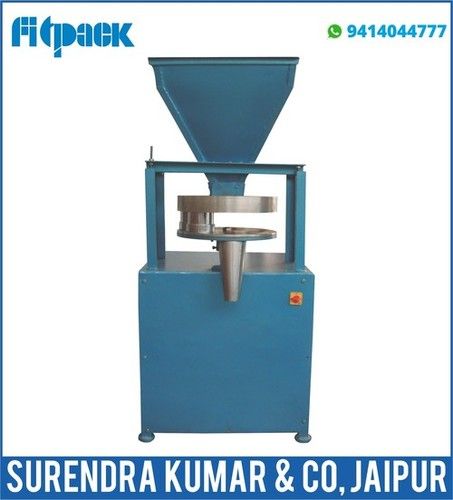

Cup Filler Machine

Product Details:

- Product Type Cup Filler Machine

- Material Stainless Steel (304 grade)

- Application Liquid & Semi-Liquid Filling (milk, curd, water, juice etc.)

- Packaging Material Plastic, Paper Cups

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control Panel

- Click to View more

X

Cup Filler Machine Product Specifications

- Easy Operation, Low Maintenance, High Precision

- PLC Control Panel

- Yes

- Cup Filler Machine

- Plastic, Paper Cups

- Automatic

- Stainless Steel (304 grade)

- 1100 mm x 900 mm x 1700 mm

- Liquid & Semi-Liquid Filling (milk, curd, water, juice etc.)

- 220-240 V

- Silver

- Approx. 300 kg

- 30-50 cups/minute

- Electric

Cup Filler Machine Trade Information

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- All India

Product Description

Advanced technology Cup Filler Machine is available for automatic filling, sealing and cutting of cups. This is widely used to fill a wide range of plastic cups for liquid. It can automatically finish the processes with its 2 , 4 , 6 and 8 heads. This Cup Filler Machine is designed to meet the production capacity of 1000-1200 CPH. Designed using high-grade stainless steel, this machine ensures to provide the best performance for years to come without any abrasion and rusting. It is a cost-saving machine available with total power of 220 V.

Advanced Filling Precision and Efficiency

Utilizing a PLC control panel, this cup filler delivers impressive accuracy (1%) and speed, processing 3050 cups per minute. The synchronized stainless steel conveyor increases throughput while minimizing noise levels below 80 dB. Designed for quick changeovers, it ensures versatility and consistent output, benefiting businesses requiring efficiency and adaptable operations in liquid and semi-liquid packaging.

Safety and Low Maintenance Design

Equipped with emergency stop, interlock protection, and easy-to-clean stainless steel (304 grade) surfaces, the machine prioritizes operational safety and hygiene. Low maintenance requirements mean reduced downtime, while the heat seal ensures each package remains secure. Its electric drive and energy-efficient performance (1.5 kW) further enhance usability, making it ideal for daily industrial use.

Customizable for Diverse Applications

Offered with one or two filling heads, the machine accommodates various cup materials including plastic and paper. It is fully automatic, computerized, and integrable with date coding, allowing traceability for end products. Whether youre a distributor, manufacturer, or trader, this equipment suits high-demand settings that require flexibility and reliable productivity.

FAQs of Cup Filler Machine:

Q: How does the cup filler machine maintain precise filling accuracy?

A: The machine uses a PLC control system combined with synchronized conveyor movement, ensuring each cup receives an accurately measured fill within 1% precision. This leads to consistent product quality and minimizes wastage.Q: What products and viscosities can be filled with this machine?

A: It is designed for low to medium viscosity liquids and semi-liquids such as milk, curd, water, juices, and similar products, making it suitable for various food and beverage applications.Q: When should I perform maintenance, and what is required?

A: Routine cleaning and inspection are recommended after each production run. The machine is constructed from stainless steel, which simplifies cleaning and reduces the need for frequent maintenance.Q: Where can this machine be used effectively?

A: Ideal for use in commercial dairies, beverage plants, and food packaging industries, the cup filler machine is designed for businesses in India that require automatic, high-precision filling and sealing.Q: What is the process for changing cup sizes or products?

A: The changeover process takes less than 15 minutes due to its user-friendly design, allowing quick adaptation for different cup sizes or product types, thereby maximizing operational flexibility.Q: How does the sealing and date coding system benefit packaging?

A: Heat sealing ensures each cup is securely closed, enhancing shelf life and safety. The date coding option enables product traceability, which is vital for quality control and compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Filling Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |