Mon to Sat: 9:00am to 6:00pm

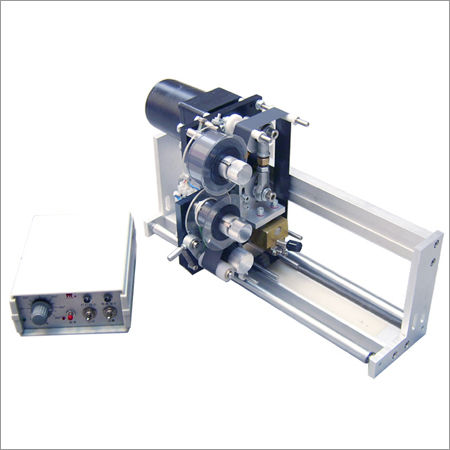

Digital Batch Coding Machine

Product Details:

- Marking Speed 30-120 pieces/min

- Marking Area 50 x 100 mm

- Condition New

- Laser Type Not Applicable (Uses Ribbon/Inkjet Coding)

- Cooling Mode Air Cooling

- Control Software Digital Control Interface

- Accuracy 0.2 mm

- Click to View more

X

Digital Batch Coding Machine Product Specifications

- Digital Control Interface

- 50 x 100 mm

- New

- 220V/50Hz, 120W

- 0.2 mm

- 420 x 250 x 260 mm

- Not Applicable (Uses Ribbon/Inkjet Coding)

- 30-120 pieces/min

- Air Cooling

Digital Batch Coding Machine Trade Information

- Delivery Point (DP), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- All India

Product Description

Digital Batch Coding Machine is designed to work constantly with high speed. It can be used in varied applications and industries as it provides around-the-clock operation. This high-tech machine comes with the life up to 12,000 hours. In addition to this, it is available with high line speed of up to 960 ft/min.

Versatile Printing Capabilities

This machine employs advanced thermal transfer or ribbon batch coding technology, suitable for an array of packaging materialspaper, cartons, films, plastics, and laminates. Adjustable font sizes and a digital interface empower accurate, high-visibility coding essential for supply chain management.

User-Friendly Digital Control and Operation

Featuring an intuitive digital control interface, users benefit from easy touch-button operation and a clear digital display. Semi-automatic automation allows quick adjustment and setup, freeing up operator time, while robust air cooling maintains optimal performance within working temperatures of 5C to 45C.

FAQs of Digital Batch Coding Machine:

Q: How does the Digital Batch Coding Machine ensure accurate printing on various packaging materials?

A: The machine utilizes thermal transfer or solid ink/ribbon technology, assuring consistent results on paper, carton, film, plastic, and laminate surfaces. Its digital control and adjustable font size (1.54 mm) ensure high precision with accuracy up to 0.2 mm.Q: What is the process for coding batch numbers, dates, or prices using this machine?

A: Operators simply set the required print information via the digital control interface, adjust the print lines (up to three) and font size, then use the touch button to begin. The semi-automatic operation enables swift and clear coding on each package.Q: Where is this batch coding machine commonly used?

A: It is extensively used in manufacturing, packaging facilities, and laboratories across India by distributors, exporters, manufacturers, and suppliers for coding on various packaging materials required for regulatory and logistical purposes.Q: What type of ink or ribbon does the machine support for printing?

A: The machine utilizes solid ink or ribbon, compatible with thermal transfer printing technology, ensuring vivid and long-lasting marks on multiple packaging substrates.Q: When should this machine be operated for optimal results?

A: For best performance, operate the machine when the ambient temperature is between 5C and 45C, which helps in maintaining consistent marking quality and prevents ink or ribbon degradation.Q: What are the key benefits of using this batch coding machine?

A: It offers reliable, high-speed coding (30120 pieces/min), adjustable print sizes, easy operation, and superior accuracy. This boosts efficiency in marking vital information, improving traceability and compliance in packaging processes.Q: How easy is it to maintain and operate the machine on a daily basis?

A: Daily operation is simplified by a digital interface, touch-button controls, and air cooling. Routine maintenance involves minimal intervention due to its robust build, while the semi-automatic design ensures lower operator fatigue.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Coding Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |