Mon to Sat: 9:00am to 6:00pm

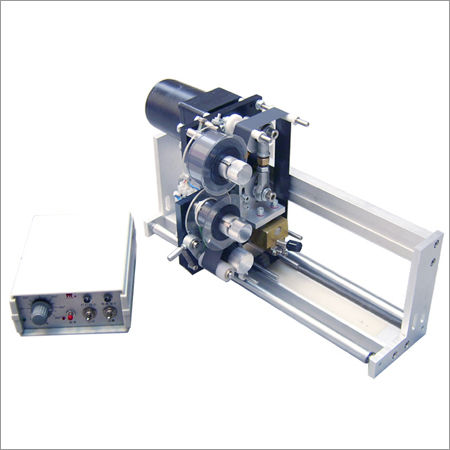

Continuous solid ink coder machine

Product Details:

- Marking Speed 300 prints/min

- Marking Area Maximum 75mm x 35mm

- Condition New

- Laser Type Not Applicable (Solid Ink Printing)

- Cooling Mode Air Cooling

- Control Software Integrated Digital Controller

- Accuracy +/- 0.1 mm

- Click to View more

X

Continuous solid ink coder machine Product Specifications

- Maximum 75mm x 35mm

- Not Applicable (Solid Ink Printing)

- 300 prints/min

- 430mm x 225mm x 300mm

- New

- 220V/50Hz, 200W

- Integrated Digital Controller

- Air Cooling

- +/- 0.1 mm

Continuous solid ink coder machine Trade Information

- Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- All India

Product Description

Continuous solid ink coder machine is a compact and high speed printing device which is used to mark informative labels and designs over the plastic pouches. It is provided with a design embedded rubber roller which is made up of synthetic materials which includes poly urethane and poly vinyl chloride to prevent damages due to corrosive chemicals. The support frame is manufactured by using premium quality steel to resist vibrations and uneven forces which ensures longer service life.

Reliable Solid Ink Printing for Multiple Materials

This machine provides consistent, high-quality marking on a variety of packaging materials, including paper, plastic, laminated films, and aluminum foil. Its versatile print area of up to 75mm x 35mm and substrate thickness capacity of 3mm make it a preferred choice for manufacturers and suppliers who need flexibility in their packaging lines.

Efficiency Meets Precision in Packaging

With an impressive speed of up to 300 prints per minute and printing accuracy of +/- 0.1 mm, the semi-automatic coder ensures swift and precise labeling. The integrated digital controller streamlines operation, allowing users to easily set the desired print parameters for different applications, whether marking cartons or pouches.

FAQs of Continuous solid ink coder machine:

Q: How does the continuous solid ink coder machine work for different packaging applications?

A: The machine uses solid ink rollers that are heated to transfer ink directly onto substrates like cartons, pouches, labels, or plastic bags. Adjustable font sizes ensure clear markings on a range of package types, suitable for various industrial labeling requirements.Q: What types of materials can this coder print on?

A: It is designed to print on paper, laminated films, plastic, and aluminum foil, provided the material thickness does not exceed 3 mm. This makes it well-suited for common packaging structures used in manufacturing and distribution.Q: When should I use solid ink blocks over traditional ink or laser marking?

A: Solid ink blocks are ideal when you need vibrant, durable prints in black, red, or blue on non-porous packaging surfaces, and when working within environments where laser marking is not feasible or required.Q: Where is this machine commonly installed or used?

A: This coder is a popular choice in manufacturing plants, packing lines, and labeling stations across India, particularly where semi-automatic automation and high throughput are essential for daily operations.Q: What is the process for changing ink colors in this machine?

A: Switching between black, red, or blue solid ink is straightforward. You simply replace the ink block roller with the desired color, ensuring the printing temperature is correctly set (70C to 180C) for optimal transfer.Q: How does the integrated digital controller benefit users?

A: The integrated digital controller simplifies machine operation, allowing precise adjustments of print parameters, speed, and temperature. This increases usability and guarantees consistent results across each batch.Q: What are the main advantages of using this coder for industrial labeling?

A: Users benefit from high marking speed, excellent print accuracy, robust construction, and compatibility with various packaging materials, leading to improved efficiency and print reliability in labeling operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Coding Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |