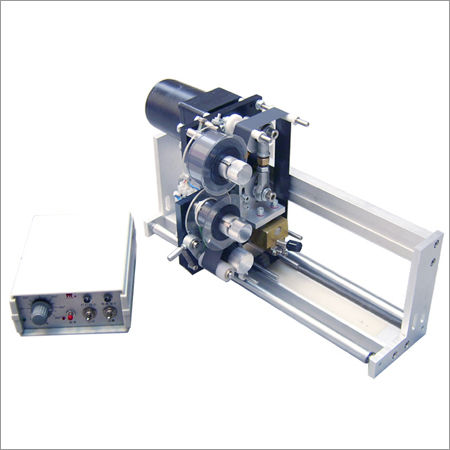

Solid Ink Coder Machine

Product Details:

- Marking Area 35 mm x 16 mm

- Marking Speed 60-80 m/min

- Condition New

- Laser Type N/A (Solid Ink Technology)

- CNC Yes

- Cooling Mode Air Cooling

- Control Software Microprocessor Controlled

- Click to View more

X

Solid Ink Coder Machine Product Specifications

- 125 W

- Air Cooling

- 430 mm x 260 mm x 220 mm

- Microprocessor Controlled

- N/A (Solid Ink Technology)

- New

- 35 mm x 16 mm

- Yes

- 0.5 mm

- 60-80 m/min

Product Description

We are the leading name in the domain of Solid Ink Coder Machine as the Exporter, Manufacturer, Service Provider, Supplier and Trading Company. The coder machines are use to print labels on paper, aluminum foils and nonferrous plastic films etc. Its printing positions are executed by the help of automatic device. Further, the quality of printing is not easy to erase or change as it is written by the help of photoelectric technique. Offered range of Solid Ink Coder Machine is made by using developed techniques and finest material.

Features:

- Automatic temperature control

- Auto counting

- Adjustable print position

- Sturdy design

Applications:

Suitable for printing labels on the surface of:

- Paper

- Nonferrous plastic film

- Aluminum foil

Key Features of the Solid Ink Coder Machine

This machine boasts solid ink technology for quick and clean printing, making it suitable for a variety of packaging films. With automatic font adjustments and multi-language support, users can efficiently print dates, batch numbers, and price information. Its robust build ensures reliability in production environments, while air cooling extends operational life.

Applications in Packaging Industries

The Solid Ink Coder Machine is widely utilized across manufacturing units, packaging suppliers, and export businesses. Its semi-automatic operation promotes user-friendly batch marking, enhancing productivity while maintaining uniform print clarity. The devices versatility supports various film types, ensuring compliance with labeling standards.

Efficient and Accurate Coding

Equipped with microprocessor control and precise marking capabilities (0.5 mm), the Solid Ink Coder Machine delivers consistently high-quality prints at rapid speeds. Operators benefit from adjustable font sizing and the ability to handle diverse character sets, making customization straightforward and reliable for both domestic and export packaging needs.

FAQs of Solid Ink Coder Machine:

Q: How does the Solid Ink Coder Machine function for date and batch printing?

A: The Solid Ink Coder Machine utilizes solid ink technology and a microprocessor-controlled system to print dates, batch numbers, and pricing onto packaging films. It supports semi-automatic operation for efficient and consistent marking.Q: What types of packaging films are compatible with this coder?

A: This machine effectively prints on Polypropylene, Polyethylene, and laminated films, making it suitable for a variety of packaging materials commonly used in industries.Q: When is it ideal to use this machine for production lines?

A: The machine is optimal for environments requiring fast and reliable marking, such as food, pharmaceutical, and consumer goods packaging, where accurate and legible prints on flexible films are essential.Q: Where can the Solid Ink Coder Machine be installed?

A: It is compact and can be installed in manufacturing units, packaging facilities, and export packaging setups across India, fitting easily into existing line setups due to its manageable dimensions.Q: What is the coding process and software control for this machine?

A: Printing is governed by a microprocessor-based control system that automates marking speed, font size, and character selection. The operator sets up the required information, which the machine then prints at up to 80 m/min.Q: How is the solid ink technology beneficial compared to traditional ink methods?

A: Solid ink technology provides clean, immediate drying, and long-lasting prints without smudging. It offers reduced maintenance, minimal mess, and robust performance over extended production runs.Q: What usage advantages does this machine offer?

A: Operators benefit from adjustable font sizes, language support, and the ability to print multiple inks (black, red, white). Its precise marking, air-cooled design, and flexibility for different packaging films enhance both efficiency and output quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Coding Machine' category

|

SURENDRA KUMAR & CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |